Introduction

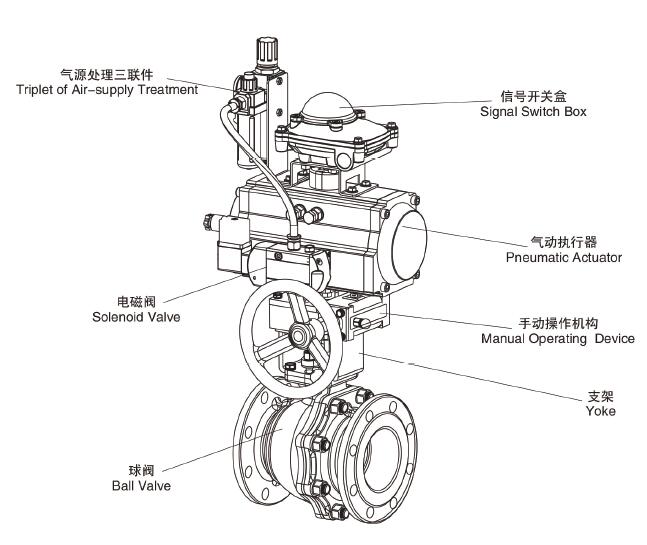

The opening and closing parts of pneumatic ball valve are driven by the valve stem and rotate from 0° to 90°, which can be used for fluid switching and adjustment. Due to its compact structure and reliable operation, it is widely used in industrial automatic control systems such as petroleum, chemical industry, teaching equipment, light industry, high-voltage equipment, pharmaceuticals, papermaking, etc. for long-distance centralized control or local control.

Operation

1. Before operation, make sure that the pipeline and pneumatic ball valve channel have been flushed.

2. The operation of the pneumatic ball valve is completed by driving the valve stem to rotate according to the size of the input signal of the actuator: when it rotates 1/4 turn (90°) in the forward direction, the valve is turned off. The valve opens when reversely rotated 1/4 turn (90°)

3. When the direction indicating arrow of the actuator is parallel to the pipeline, the valve is open; when the indicating arrow is perpendicular to the pipeline, the valve is closed.

Daily maintenance

Having a long service life and maintenance-free period will depend on several factors: normal operating conditions, maintaining a harmonious temperature/pressure ratio, and reasonable corrosion data.

1. pneumatic ball valves should be placed in a ventilated and relatively dry closed room, and both ends of the valve passage should be blocked to prevent debris from entering the interior and causing wear.

2. If the pneumatic ball valve is not to be used immediately, so the storage time is relatively long, it should be checked and cleaned regularly, and anti-rust oil should be applied after cleaning.

3. After installation, we must also regularly check whether the pneumatic ball valve is working normally and check its aging degree. The main inspection items include:

(1) The wear of the sealing surface of the pneumatic valve;

(2) The wear of the trapezoidal thread of the stem and stem nut;

(3) Whether the packing is outdated and invalid, if so, replace it in time;

(4) After the valve is repaired and assembled, the sealing performance test should be carried out.

How to replace spare parts

Common wearing parts of pneumatic ball valves are stem packing and sealing seat ring. Please follow the steps below to replace spare parts regularly.

1. Disassembly

1) With the valve in the half-open position, flush and remove any hazardous substances that may exist inside and outside the valve body.

2) Close the pneumatic ball valve, remove the connecting bolts and nuts on both flanges, and then completely remove the valve from the pipeline.

3) Disassemble the drive device in sequence - actuator, connecting bracket, lock washer, valve stem nut, butterfly spring, glam, wear plate, valve stem packing.

4) Remove the body cover connecting bolts and nuts, separate the bonnet from the body, and remove the bonnet gasket.

5) Make sure the ball is in the "closed" position, which will allow it to be easily removed from the body and then the seat.

6) Gently push the valve stem down through the hole in the valve body until it is completely removed, then take out the O-ring and the packing under the valve stem.

Note: Please be careful to avoid scratching the stem surface and the valve body stuffing box sealing part.

2. Reassembly

1) Clean and inspect the removed parts. It is strongly recommended to replace the seat and valve cover gaskets and other seals with a spare parts kit.

2) Assemble in reverse order of disassembly.

3) To the specified torque, cross-tighten the flange connection bolts.

4) Tighten the stem nut to the specified torque.

5) After installing the actuator, input the corresponding signal to drive the valve core to rotate by rotating the valve stem, so that the pneumatic ball valve can be opened and closed.

6) If possible, perform a pressure tightness test and performance test on the valve according to the relevant standards before reinstalling the piping.

Meanwhile, attention shall be paid to the follows

●When the pneumatic ball valve is closed, there is still pressurized fluid inside the valve body;

●Before maintenance, release the line pressure and keep the pneumatic ball valve in the open position;

●Before maintenance, disconnect the power supply or gas source;

●Before maintenance, disengage the actuator from the bracket;

●The disassembly and decomposition operation can only be carried out after it is confirmed that the upstream and downstream pipelines of the pneumatic ball valve have been depressurized;

●During disassembly and reassembly, care must be taken to prevent damage to the sealing surfaces of parts, especially non-metallic parts, special tools should be used when removing O-rings

●The bolts on the flange must be tightened symmetrically, gradually and evenly during assembly

●The cleaning agent should be compatible with the rubber parts, plastic parts, metal parts and working medium (such as gas) in the pneumatic ball valve. When the working medium is gas, gasoline (GB484-89) can be used to clean metal parts. Clean non-metallic parts with pure water or alcohol

●The disassembled single parts can be cleaned by dipping. The metal parts with undecomposed non-metal parts can be scrubbed with a clean and fine silk cloth impregnated with cleaning agent (to prevent the fibers from falling off and adhering to the parts). When cleaning, all grease, dirt, glue, dust, etc. adhering to the wall must be removed

●The non-metal parts should be removed from the cleaning agent immediately after cleaning, and should not be soaked for a long time

After cleaning, it needs to be assembled after the cleaning agent on the wall surface to be washed has evaporated (can be wiped with a silk cloth not soaked in the cleaning agent), but it should not be left for a long time, otherwise it will rust and be polluted by dust

●New parts also need to be cleaned before assembly

●Use grease for lubrication. Grease should be compatible with pneumatic ball valve metal materials, rubber parts, plastic parts and working medium.

●During assembly, no metal chips, fibers, grease (except those specified for use), dust, other impurities, foreign objects, etc. should be allowed to contaminate, adhere or stay on the surface of the parts or enter the inner cavity

Contact: Zhang Heng (Bill )

Phone: 86 13634285240

Tel: 86 0577 86915200

Email: cspneumatic@hotmail.com

Add: Yongqiang High Technology Developing Zone, Wenzhou, China.