1. Introduction

Pneumatic double disc gate valve use wear-resistant toughened structural ceramics, which solves the problem of easy erosion and service life of the sealing surface due to material erosion. The service life is 5-10 times longer than that of ordinary material valves. It brings ideal use effects and economic benefits to users, is conducive to equipment maintenance and operation adjustment, so that the safety and economy of the overall operation are significantly improved.

2. Working principle

The working principle of the pneumatic ceramic double gate valve: With the help of the external power provided by the cylinder or hand wheel, the valve stem drives the valve plate to move up and down to realize the opening and closing of the valve. The valve opening and closing process relies on the pretension of the spring between the double gate plates. The valve plate is in close contact with the valve seat to achieve sealing.

When the air source is introduced from the upper air inlet, the valve stem drives the valve plate to move downward, and the valve is closed. When the air source is introduced from the lower air inlet, the valve stem drives the valve plate to move upward, and the valve opens. A spring is loaded between the valve plate and the valve seat. The spring force always pushes the valve plate against the valve seat to ensure the sealing of the valve, and allows the valve plate to move vertically up and down, which helps to compensate for the thermal expansion and contraction of the valve parts, and It can overcome the influence of any back pressure changes on the seal and prevent particulate media from entering between the two sealing surfaces.

During the opening and closing process, the valve plate can rotate to make grinding and polishing between the sealing surfaces. Also, because the valve body is eccentric to the passage, vortex flow will be generated when the material is opened and discharged, and the formed material vortex will clean the valve by itself. All these characteristics make this valve have a long service life and provide a reliable guarantee for the safe operation of your system.

3. Scope of application

Pneumatic double disc gate valve is used for the inlet and outlet valves of the dry ash system of the thermal power plant. It can also be used for opening and closing the pipelines with wear and tear of dry dust, water, steam and other media such as steelmaking, papermaking, chemical industry and so on.

4. Features

1) The material port is fully circulated without any obstructions, with compressed air automatic blowing and blocking device, and less dust jam and accumulation;

2) It adopts wear-resistant toughened structural ceramic seal, which has high mechanical strength and good wear resistance;

3) It can be installed at any position and angle.

4) Compact structure and easy installation.

5) The sealing pair can be replaced, saving cost.

5. Technical parameter

Nominal diameter: DN40-DN350

Nominal pressure: PN1.0-PN1.6 Mpa

Air pressure of pneumatic actuator: 0.3-0.6 Mpa

Operating temperature: up to 200 degrees Celsius

Applicable medium: fly ash, dry dust, gas, water, etc.

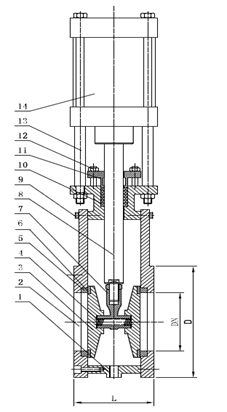

6. Part Name

|

S/No |

Part Name |

Material |

|

1 |

Main valve body |

WCB |

|

2 |

Side valve body |

WCB |

|

3 |

Disc |

WCB |

|

4 |

Clapper spring |

304 |

|

5 |

Seat seal |

Ceramic |

|

6 |

Disc seal |

Ceramic |

|

7 |

Disc holder |

WCB |

|

8 |

Stem |

ASTM 1045+Cr |

|

9 |

bolt |

A193 B7 |

|

10 |

filler |

PTFE |

|

11 |

Packing gland |

WCB |

|

12 |

Gland bolt |

A193 B7 |

|

13 |

Bracket |

CS+galvanized |

|

14 |

Aluminum alloy |

7. Installation, use and maintenance

1) Read this manual carefully before installation, and check the valve model, diameter and technical parameters.

2) It is strictly forbidden to weld the flange after the valve is installed. The valve installation distance reserved for the optional pipeline should be appropriate, and gaskets should be added on both sides of the flange.

3) The center of the two pipelines and the center of the valve diameter should be coaxial. The flange surface should be flat. No large deviation of the flange surface is allowed to ensure the clamping and normal operation of the valve. The tightening of the bolts should be even and symmetrical.

4) If there is dust leakage at the packing when the valve is in use, the packing gland bolts need to be adjusted regularly.

5) After the initial operation, if it is not used for a long time the dust in the inner cavity of the valve must be removed to avoid scaling and hardening, which will affect the opening and closing of the valve. When restarting, check whether there is adhesion or rust between the packing of the valve stem and the cylinder seal. If there is slight rust, add oil.

8. Operation

a) On-site manual pneumatic control

The manual double gate valve can directly operate the hand wheel to open and close, and the manual pneumatic device uses the kinetic energy of compressed air to operate the manual valve to directly realize the on-site manual opening and closing of the valve.

b) Centralized control system

The valve's own control device can accept the 220V/110V/24VDC voltage control signal provided by the centralized control system to realize remote control;

c) PLC or DCS system

The valve can accept 4-20mA current signal from PLC or DCS system to realize automatic control.

9. Common faults and troubleshooting methods

|

Fault |

Cause |

Solution |

|

Valve is not sealed |

There is a foreign body stuck |

Remove foreign objects |

|

Deposited slag in the valve cavity |

Remove deposits |

|

|

Damaged seal |

Replace |

|

|

Leakage at the flange joint |

Uneven bolt tightening |

Tighten the bolts evenly |

|

Damaged flange working surface |

Grind the flange working surface |

|

|

Damaged gasket |

Replace the gasket |

|

|

The valve cannot be opened or closed |

Loose or failure of transmission parts |

Adjust or replace damaged parts |

|

Insufficient air pressure, serious air leakage |

Check and repair the gas supply line |

|

|

Aging and failure of pneumatic components |

Replace damaged pneumatic components |

|

|

Deposited slag in the valve cavity |

Remove |

Contact: Zhang Heng (Bill )

Phone: 86 13634285240

Tel: 86 0577 86915200

Email: cspneumatic@hotmail.com

Add: Yongqiang High Technology Developing Zone, Wenzhou, China.