Introduction

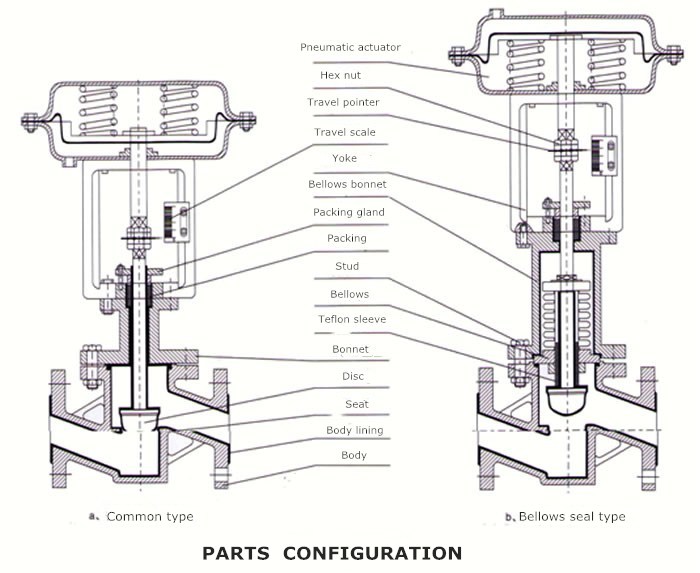

Bellow type control valve with pneumatic actuator can control the flow rate of high-strength corrosive media such as acid and alkali, as well as toxic and volatile gas and liquid media, so it is widely used in chemical industry, metallurgy, medicine and other industries.

Features

1. It has compact structure, light weight and sensitive action;

2. The fluid channel is S streamlined, the pressure drop loss is small, and the valve capacity is large;

3. The parts of the valve body in contact with corrosive media are made of corrosion-resistant and anti-aging polyperfluoroethylene propylene;

4. High-pressure lining fluorine plastic technology, and adopts polytetrafluoroethylene bellows sealing.

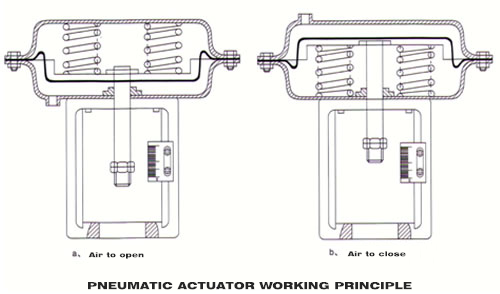

How diaphragm type pneumatic actuator works

The actuator is an important part of the automatic control system in the production process of the pneumatic control valve. It has two forms of action, AIR TO OPEN and AIR TO CLOSE.

AIR TO OPEN:

When the signal pressure increases, the push rod goes inside of the membrane chamber. In case that there is emergency of air or electric failure, it will automatically close the valve and keep the normally closed position ( Figure 2a).

AIR TO CLOSE:

When the signal pressure increases, the push rod go inside of the membrane chamber. In case that there is an emergency of air or electric failure, the valves will stay in normally open position ( Figure 2b).

Specifications

|

Nominal diameter mm |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

|||||

|

Seat diameter mm |

10 |

12 |

15 |

20 |

25 |

32 |

40 |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

||

|

Rated flow coefficient Kv |

Linear |

1.8 |

2.8 |

4.4 |

6.9 |

11 |

17.6 |

27.5 |

44 |

69 |

110 |

176 |

275 |

440 |

690 |

1100 |

1760 |

|

|

equal percentage |

1.6 |

2.5 |

4 |

6.3 |

10 |

16 |

25 |

40 |

63 |

100 |

160 |

250 |

400 |

630 |

1000 |

1600 |

||

|

Nominal pressure MPa |

0.6, 1.0, 1.6, 2.5 |

|||||||||||||||||

|

stroke mm |

10 |

16 |

25 |

40 |

60 |

100 |

||||||||||||

|

Diaphragm effective area Ae (cm) |

280 |

400 |

630 |

1000 |

16000 |

|||||||||||||

|

Flow characteristics |

Straight line, equal percentage |

|||||||||||||||||

|

Working temperature ℃ |

-30 ℃ ~+150 ℃ |

|||||||||||||||||

|

Inherent adjustable ratio R |

50:1 |

|||||||||||||||||

|

Signal rangePr |

20~100, 40~200, 20~60, 60~100, 80~240 |

|||||||||||||||||

|

Air source pressure MPa |

0.14, 0.4 |

|||||||||||||||||

|

Allowable differential pressure MPa |

Unlimited belt locator |

5.3 |

3.7 |

23 |

13 |

0.85 |

0.74 |

0.47 |

0.30 |

0.27 |

0.18 |

0.11 |

0.12 |

0.08 |

0.05 |

0.04 |

0.03 |

|

|

with locator |

6.4 |

6.4 |

5.5 |

3.01 |

2 |

1.7 |

1.1 |

0.71 |

0.63 |

0.41 |

0.26 |

0.28 |

0.20 |

0.11 |

0.08 |

0.05 |

||

|

Takeover thread |

M16*15 |

|||||||||||||||||

Main performance

|

project |

General regulating valve |

Medium temperature (flexible graphite packing) or bellows-sealed regulators |

||||||||||||||||

|

without locator |

with locator |

without locator |

with locator |

|||||||||||||||

|

Basic knowledge difference % |

±5 |

±1 |

±15 |

±4 |

||||||||||||||

|

Return difference % |

±3 |

±1 |

±10 |

3 |

||||||||||||||

|

dead zone% |

±3 |

±0.4 |

±8 |

1 |

||||||||||||||

|

Always point deviation % |

open air |

starting point |

±2.5 |

±1 |

±6 |

±2.5 |

||||||||||||

|

end |

±5 |

±15 |

||||||||||||||||

|

Qiguan |

starting point |

±5 |

±15 |

|||||||||||||||

|

end |

±5 |

±6 |

||||||||||||||||

|

Rated formation deviation % |

2.5 |

2.5 |

6 |

2.5 |

||||||||||||||

|

allowable leakage |

Adjustable L/h |

10-4×valve rated capacity JP |

||||||||||||||||

|

Adjust the shut-off valve |

Seat Diameter |

20 |

25 |

40 |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

||||||

|

allowable leakage |

Soft Seal: Class VI |

|||||||||||||||||

|

Rated flow coefficient deviation% |

±10 |

|||||||||||||||||

|

Inherent flow characteristic deviation |

Comply with the slope requirements specified in IEC534-1976 and GB/T 13927 |

|||||||||||||||||

Main parts

|

Part Name |

Material |

|

valve body, valve cover |

HT200, ZG230~450, ZG1Cr18Ni9Ti |

|

lining material |

F46, F4, F3, PO, PE, X, X3, PFA |

|

Spool |

1Cr18Ni9Ti |

|

Bellows |

PTFE |

|

filler |

PTFE, flexible graphite |

|

spring |

60Si2Mn |

|

Membrane cover |

A3 |

|

valve stem, push rod |

2Cr13/1Cr18Ni9Ti |

|

bushing |

2Cr13 |

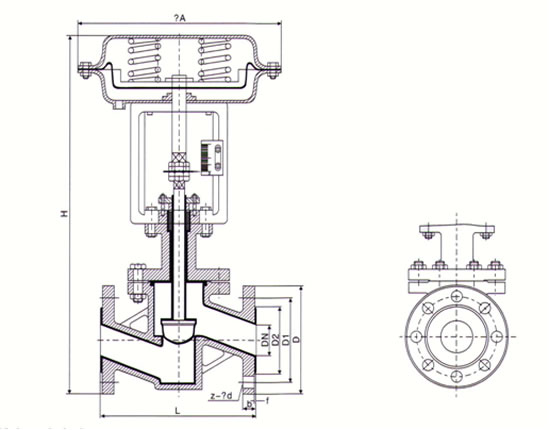

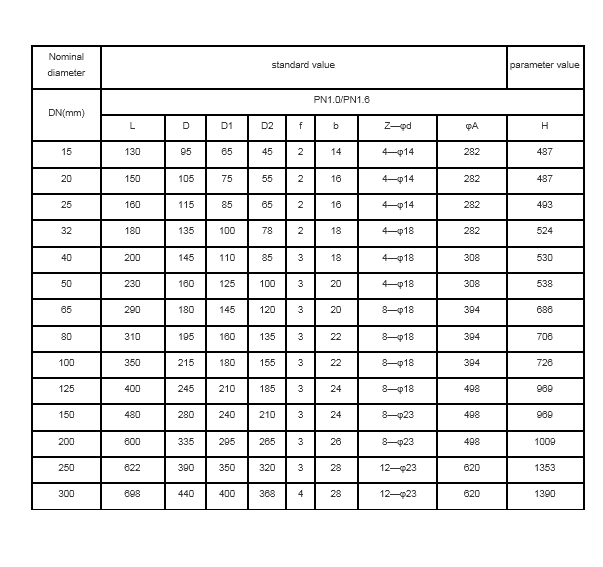

Main connection size

Contact: Zhang Heng (Bill )

Phone: 86 13634285240

Tel: 86 0577 86915200

Email: cspneumatic@hotmail.com

Add: Yongqiang High Technology Developing Zone, Wenzhou, China.