Introduction

Pneumatic teflon lined three-way ball valve is composed of rack & pinion pneumatic actuator and three-way ball valve, which is used as rotary cut-off our modulating valve. The inner wall of the valve body and the inner valve components in contact with the fluid are all made of high-temperature molded PTFE, PFA, FEP and other anti-corrosion materials can cut off the contact between the corrosive medium and the valve shell.

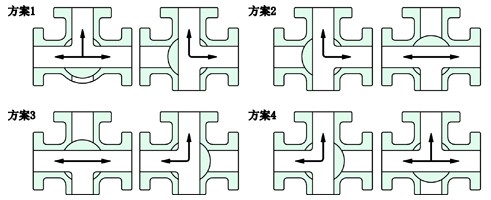

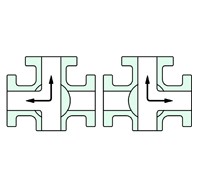

L Type or T type

Pneumatic three-way PTFE lined ball valve is divided into L type and T type. The flow direction of the medium is shown in the figure below. The L-type pneumatic three-way PTFE lined ball valve is suitable for switching the flow direction of the medium, which can connect two mutually perpendicular channels: the T-type pneumatic three-way PTFE lined ball valve is suitable for the splitting, confluence or flow direction switching of the medium. Each channel is connected to each other or two of them are connected. The pneumatic three-way PTFE lined ball valve generally adopts a three-seat structure, and can also adopt a four-seat structure according to user requirements.

"T" type flow direction

"L" shape flow diagram

Working principle

The valve can be equipped with a valve positioner input control signal (4-20mADC or 1-5V DC) air source to control the operation, and can also be equipped with a travel limit switch, a solenoid valve, a pressure reducing valve and a 0.4-0.7MPa air source. The switch operation is realized, and two pairs of passive contact signals are sent to indicate the switch of the valve

It can not only realize the switching of the flow direction of the medium, but also make the three channels communicate with each other. At present, one channel can also be closed, and the other two channels can be connected, so as to flexibly control the confluence or diversion of the medium in the pipeline. It is widely used in the control of strong corrosive media such as acid and alkali and the control of gas and liquid media such as toxic, volatile and permeable.

Performance and Features

1. Corrosion resistance: almost able to resist the corrosion of all media (including concentrated nitric acid and aqua regia);

2. The flow capacity is large, and the flow direction of the medium is not restricted;

3. Good sealing performance and small leakage: the sealing valve seat is made of PTFE, which has reliable sealing and self-lubrication, and has low leakage;

4. In addition to general gas and liquid, it is more suitable for high viscosity and medium with fibrous and suspended soft particles;

5. It can realize the switching of the flow direction of the medium in the pipeline, and can also connect or close the two channels that are perpendicular to each other.

6. Equipped with multi-spring rack and pinion pneumatic actuators,which are convenient for various environments and are currently the most widely used control and cutting systems.

Technical specification

|

Nominal diameter DN(mm) |

15~300 |

|

Nominal pressure (MPa) |

PN1.0, 1.6, 2.5MPa |

|

Body form |

Two-stage valve body |

|

Connection Type |

Flange |

|

Spool form |

"O" type three-way ball valve core |

|

seal packing |

Polytetrafluoroethylene (PTFE) |

|

Flow characteristics |

Approximate quick opening |

|

range of motion |

0~90° |

|

Leakage Q |

Zero leakage |

|

proper temperature |

PTFE≤150℃ |

|

basic error |

With positioner: less than ±2% of full stroke |

|

dead zone |

With positioner: less than 2% of full stroke |

|

Adjustable range |

250:1 |

|

Configure the actuator |

DA, SR, AW series, single or double acting, pneumatic actuators |

|

way to control |

Switch two-position control, 4-20mA analog control |

Actuator specification

|

Actuator model |

DA , SR, AW series single and Double Acting Pneumatic Actuators |

|

Air supply |

0.4~0.7MPa |

|

supply interface |

G1/4", G1/8", G3/8", G1/2" |

|

ambient temperature |

-30~+70℃ |

|

Form of action |

(1)Single-acting actuator: air-close (B)--valve position open (FO) when gas is lost;

air-open (K)--valve position-close

(FC) when gas is lost air-close (B) )--Valve position hold (FL) when degassing; Air-to-open (K)--Valve position hold (FL) when degassing |

|

Accessories available |

Positioner, solenoid valve, air filter pressure reducer, retaining valve, travel switch, valve position transmitter, hand wheel mechanism, etc. |

Part material

|

Part Name |

Material name |

|||

|

valve body |

WCB+F46 or F4 |

CF8+F46 or F4 |

CF8M+F46 or F4 |

CF3M+F46 or F4 |

|

Ball |

2Cr13+F46 or F4 |

304+F46 or F4 |

316+F46 or F4 |

316L+F46 or F4 |

|

stem |

2Cr13+F46 or F4 |

304+F46 or F4 |

316+F46 or F4 |

316L+F46 or F4 |

|

sealing ring |

PTFE |

|||

|

Applicable media |

Corrosive media such as strong acid and alkali |

|||

Note: F4=PTFE, F46=FEP

How to order

(1) Valve body parameters:

a. nominal diameter;

b. working pressure;

c. process medium,;

d. application occasion;

e. valve body material.

(2) Actuator parameters:

a. actuator form,

b. control mode,

c. control signal (4-20mA, 1-5V),

d. action mode (air-open, air-close)

Contact: Zhang Heng (Bill )

Phone: 86 13634285240

Tel: 86 0577 86915200

Email: cspneumatic@hotmail.com

Add: Yongqiang High Technology Developing Zone, Wenzhou, China.